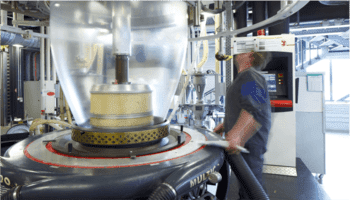

Highest Quality Purging Compound for Extruders

UNICLEANPLUS™ purging compound for extruders proves to be highly efficient in cleaning your extrusion machine. Our purging material for thermoplastic extruders helps to optimise issues like material wastage, untimely breakdown and production downtime.

Extrusion molding with long-run and high output can suffer due to high scrap rate, extended changeovers, and long periods of dead time. We deliver versatile and highly efficient purging compounds for extruders. Our uniquely formulated purging compound can efficiently combat the challenges that extrusion molders face and ensure high performance. With its unique formulation, our purging material for extruders effortlessly removes material build-up and contaminates.

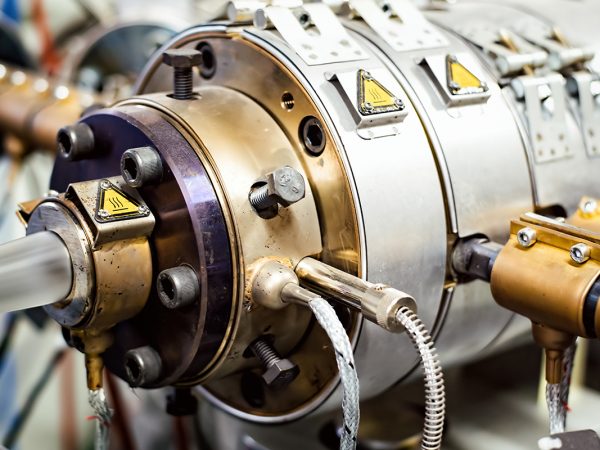

Troubleshooting Tips to Clean Extrusion Machine with Purging Material for Extruder

- Check your barrel temp that matches the UNICLEANPLUS™ purging compound grade.

- Start-up with the screw in an empty material position for cleaning the hopper and feed throat!

- You may leave the screens at the time of purging.

- Feed two-barrel capacity of purging compound into the extruder.

- Feed our purging material into the barrel as per the rate of screw speed.

- Start purging at a low speed.

- Once you see the purging compound comes out from the head, increase the screw speed to a safe level.

- When you see the purging compound coming out smoothly from the barrel, stop the screw and allow it to sit in the barrel for a few minutes.

- Then start screw rotation at maximum screw speed to purge up until the purging compound completely comes out from the barrel.

- Inspect the purge lumps manually to see whether the lumps are free of contamination or not.

- If you find the presence of contamination, then repeat the purging process.

- If no contamination is found, then start your resin at safe screw speed.

Tips to Get the Best Results with Purging Compound for Extruders

- Remove resin from the barrel by extruding the purge material through the system.

- Purge with the purging compound grade for cleaning the screw and barrel.

- Use the suitable highest quality purging compound grade to remove the maximum deposit.

- Contact a purging process expert at UNICLEANPLUS™ to know the right procedures.

- You can clean the extruders with a die attached by using our highly efficient purging compound. It helps in purging all of the resin from the die, barrel, and screw.

Benefits of Using UNICLEANPLUS™ Purging Material for Extruders:

- Experience effortless and highly efficient purging procedure

- Our purging compound removes all deposits from the screw and barrel.

It is essential to use the right product and process for purging screws for extrusion. Using wrong products or tools can lead to unexpected production issues. UNICLEANPLUS™ purging compound acts fast and ensures thorough cleaning.

If you want more information about our recommended purging procedures, allow our expert team to answer your questions! We can help know how the UNICLEANPLUS™ purging compound can cover your problem areas and deliver a comprehensive solution for your extrusion process.

Need trial sample

We are here to Help. Learn more about the benefits of UNICLEANPLUS™ purging compounds.