Purging Compound

UNICLEANPLUS™- Leading Purging Compound Supplier

UNICLEANPLUS™ is a highly reliable and leading purging compounds supplier that provides highly effective purging solutions for various applications. Our highly efficient purging compounds are developed to cover a wide array of operating temperatures, equipment types, and process applications. At UNICLEANPLUS™, we provide the highest quality purging material to address the challenges of the thermoplastic processors that enhance their performance and operations.

Purging compounds are essential for maintaining the efficiency and longevity of your equipment. Our purging compounds are specially formulated to clean extruders, injection molding machines, and blow molding machines. By using UNICLEANPLUS™ purging compounds, you can significantly reduce downtime and material waste, ensuring a smoother production process.

Highly Efficient Purging Compound for Plastic

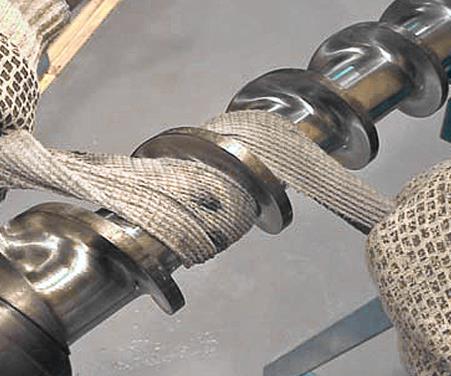

Purging compounds play an essential role in modern thermoplastic processors. Our purging compound for plastic is designed for parameters and operational processes to provide a competitive advantage. Whether it is about eliminating carbon buildup in barrel assemblies or screws, our purging material proves to be efficient enough!

As a reliable purging compound supplier, we have a significant impact on lowering the scrap rates, improving processing efficiency, and assuring the right equipment maintenance. With our purging products, you can experience a reduction in polymer change time or reductions in material consumption while color changeovers, that enhance operational margins. Our purging products can help you experience an increase in labor and equipment uptime that allows your organizational assets fully leveraged and enhances the manufacturing process.

A Complete Guide to Purging Compounds and Why They Matter

In plastics processing, keeping machines clean is essential for consistent production, smooth changeovers, and high-quality output. Resin changes, color changes, and material contamination can slow a line down and increase operational costs. This is where Purging Compounds, also known as purging materials, play an important role. UNICLEANPLUS™ has become a trusted choice in the industry for companies that want a reliable, easy-to-use solution backed by a dependable Purging Compound Supplier.

This guide explains what a purging compound is, how it works, and how you can use it the right way. It also covers why UNICLEANPLUS™ stands out as an effective Purging Compound for Plastic processors.

What Is a Purging Compound?

A purging compound is a cleaning material used to remove old resin, degraded plastic, color deposits, and contaminants from processing equipment. It is used in machines such as injection molding, blow molding, extrusion, and compounding lines.

During production, plastic residue builds up in the barrel, screws, hot runner, and die of the machine. Over time, this leads to black specks, gels, streaks, discoloration, or inconsistent melt quality. A purging compound clears this residue, helping the machine run clean and stable again.

Unlike traditional methods like flushing with virgin resin or performing manual teardown, purging compounds are faster, safer, and more cost-effective. They are specifically designed to melt, scrub, lift, and remove stubborn deposits that normal materials cannot handle. For many processors, the switch to a high-performance Purging Material becomes a long-term maintenance upgrade.

How Purging Compounds Work

Purging compounds work through one of three main methods: mechanical, chemical, or hybrid. Each method has a specific purpose, and the right choice depends on the type of contamination, equipment, and production needs.

Mechanical

Mechanical purging compounds clean through physical scrubbing. They contain high-viscosity carriers and abrasive fillers that create friction inside the barrel and screw. As the compound moves through the machine, it scrapes off built-up resin, carbonized deposits, pigments, and degraded materials.

Mechanical purging is ideal for:

Routine color changes

Standard resin changeovers

Removing physical buildup and contamination

Machines that cannot use chemical reactions

Because mechanical compounds work through movement and friction, they are safe for most general-purpose applications and do not rely on heat-activated reactions.

Chemical

Chemical purging compounds use reactive agents that break down and lift contamination at the molecular level. When the compound reaches a specific temperature range, its cleaning chemicals activate, loosening stubborn or carbonized resin inside the machine.

Chemical purging is useful for:

Deep cleaning during shutdown or startup

Tough resin changes (such as from PVC, PC, or Nylon)

Removing degraded or oxidized deposits

Cleaning parts of the machine with low flow

These compounds require proper temperature control, but they are extremely effective for contamination that mechanical purging cannot reach.

Hybrid

Hybrid purging compounds combine both mechanical scrubbers and chemical cleaners. This gives them a powerful dual action: the chemicals break down deposits while the mechanical fillers wipe the barrel clean.

Hybrid compounds are suited for:

Fastest and most difficult color changes

Full cleaning before shutdown

Changeovers between materials with different melt characteristics

Removing a mix of pigment, resin, and carbon contamination

For many processors, hybrid purging offers the most complete clean with the shortest downtime.

Benefits of Using Purging Compounds

Using a high-quality purging compound delivers immediate and long-term advantages for plastic processors. Below are the key benefits that companies experience after switching to a specialized Purging Compound for Plastic.

Reduce downtime

One of the biggest advantages is faster changeovers. Instead of spending long periods flushing with virgin resin or stopping the line for manual cleaning, purging compounds clear contamination quickly. This means production resumes sooner, which directly boosts output.

Shorter downtime is especially important for:

Frequent color changes

Small batch production

High-value machinery

Tight delivery schedules

A clean machine runs smoothly and stays productive.

Improve efficiency

Purging compounds improve processing efficiency by stabilizing melt flow and ensuring consistent output. A clean barrel and screw eliminate flow interruptions, uneven melt temperatures, and pressure fluctuations.

This leads to:

Uniform color during production

Stable cycle times

Lower reject rates

Less troubleshooting for operators

Better efficiency also extends the lifespan of machinery by reducing the stress caused by contamination buildup.

Cost savings

Although some processors rely on inexpensive methods like flushing with virgin resin, this often costs more in the long run. Virgin resin consumption increases, energy is wasted, and operators spend more time managing the machine.

Purging compounds reduce costs by:

Cutting waste and scrap

Reducing labor time

Lowering resin usage

Preventing machine damage

Shortening changeovers

The more often a facility changes color or resin, the more significant the cost savings become.

Machine and operator safety

Purging compounds support safer operation by reducing the risks associated with manual cleaning. When machines are opened for teardown, workers face exposure to hot equipment, sharp components, and fumes from degraded plastic.

With a proper Purging Material, cleaning happens through the barrel, eliminating the need for unnecessary disassembly.

A clean machine also runs at stable temperatures, minimizing safety hazards like:

Resin degradation

Overheating

Pressure spikes

Material leaks

Using a proven purging compound protects both equipment and the people operating it.

How to Use Purging Compounds

Different types of purging compounds have different instructions. Understanding how to use each type ensures maximum cleaning performance and helps avoid unnecessary waste.

For ready-to-use products

Ready-to-use purging compounds come pre-blended with all necessary components. They do not require mixing and can be fed directly into the machine.

To use them:

Empty the machine of the current resin.

Set the temperature to the recommended range.

Introduce the purging material.

Run the screw at a moderate speed for several cycles.

Continue until the barrel is clear.

Follow with a small amount of the next production resin.

These compounds are ideal for quick changeovers and daily cleaning routines.

For concentrates

Concentrated purging compounds need to be mixed with a compatible carrier resin such as HDPE, PP, or another recommended material.

The process involves:

Mixing the concentrate at the proper ratio (often 10–50%).

Running the blend through the screw.

Allowing the compound to activate chemically or mechanically.

Flushing with the next production resin.

Concentrates offer flexibility and allow processors to use their own base resin during cleaning.

For mechanical types

Mechanical purging compounds require movement of the screw to create friction and scrub residue. Proper screw rotation is essential to achieve the best cleaning results.

Steps include:

Setting a moderate screw speed.

Avoiding long soak times (mechanical compounds don’t need them).

Running short bursts of forward and reverse for heavy contamination.

Flushing until no residue remains.

Mechanical purging is simple, effective, and safe for most equipment.

Why UNICLEANPLUS™?

UNICLEANPLUS™ has established itself as a trusted Purging Compound Supplier for companies seeking performance, reliability, and value. The brand offers a full line of Purging Compounds designed for injection molding, extrusion, blow molding, and other plastic processing applications.

Here’s why manufacturers choose UNICLEANPLUS™:

1. Versatile solutions for every machine

The product range includes mechanical, chemical, and hybrid purging materials. Whether you need a fast color change or a deep clean, UNICLEANPLUS™ has a matching formula.

2. Fast results with minimal waste

UNICLEANPLUS™ compounds are engineered to deliver quick cleaning action. Most machines require less material compared to traditional purging methods, reducing both waste and cost.

3. Safe for equipment

Each product is designed to protect barrels, screws, and hot runners. The compounds operate within normal temperature ranges and do not cause corrosion or abrasive damage.

4. Consistent quality

UNICLEANPLUS™ maintains strict quality controls, ensuring that every batch performs the same. This gives processors confidence during critical production runs.

5. Reduced downtime and improved productivity

Customers report faster color changes, fewer defects, and smoother startup and shutdown routines. The compounds help facilities maximize uptime and meet production deadlines.

6. Strong technical support

UNICLEANPLUS™ provides guidance on choosing the right purging material and using it effectively. This support helps companies get the best possible results with minimal trial and error.

7. Competitive pricing

Despite high performance, the products are priced competitively, offering excellent value for companies of all sizes.

UNICLEANPLUS™ combines efficiency and ease of use, making it a reliable partner for any plastics processor looking to improve machine cleanliness and reduce operational challenges.

Purging Compound FAQs

Purging compounds are specific cleaning materials used to clean and wash out the interior of various processing equipment, such as machines for injection molding, extruders, and other plastic-making machinery, to eliminate residue and contaminants.

There is the use of advanced formulations making it possible for UNICLEANPLUS’s purging compound to eliminate any build-up of polymer and contaminants from the equipment. This cleaning process makes certain that one can have a smooth transition between various materials and reduces downtime.

It is possible to use our purging material in various types of machinery, like injection molding, extruders and equipment for blow molding along with various other types of equipment.

The interval between the uses of purging compound depends on the nature of your production and the change of materials. It is wise to use a purging compound when you change material and colours. It is also necessary to use these cleaning materials if you notice a decrease in production quality.

Without any doubt, we can say that it is safe to use our purging material as we formulate it to be safe for use. However, it is always good to follow the instructions and safety guidelines that we offer. This will ensure proper handling and use.

We design our purging material for plastic processing equipment. If you need to use our purging compound for metal equipment do contact us and follow the manufacturer’s guidelines.

With every purging compound that we supply we offer certain instructions which you need to follow. Typically, the process involves adding the material, running it through the equipment and then cleaning any remaining residue.

It is possible to enhance production efficiency using our purging materials. You can reduce downtime, and material waste and improve the quality of the final product.

While storing the material you need to ensure that it is not exposed to direct sunlight and extreme temperatures. You also need to ensure that the bag is tightly sealed to prevent contamination.

You can purchase our purging materials from our authorised dealers or directly contacting us. You can contact us to gather more information on buying and the distribution process.

Need trial sample?

We are here to Help. Learn more about the benefits of UNICLEANPLUS™ purging compounds.